|

|

#511

|

|||

|

|||

|

I have 4.0, Pete.

Actually 4.5, as of last Thursday. I saw the post you referenced, and I can wrap my mind around making a smooth crown, but I'd like to do a carved crown with some egg and dart or similar carvings on it to up the wow factor.. (of course.  ) )I'm going to a 3 day Aspire camp in May, hopefully I'll be able to step up my game a notch above stupid beginner..  Maybe I'll take this above pic along. Maybe I'll take this above pic along. |

|

#512

|

|||

|

|||

|

To answer your other question, Pete,

The room will be drywalled first, then the sheets could be glued/nailed to the framing through the drywall. I could always sheet the room in OSB, instead of drywall, then nail wherever I wanted. Thanks for the input guys, its much appreciated. |

|

#513

|

|||

|

|||

|

The instruction videos cover it pretty well but there is also a 2 rail sweep video here

|

|

#514

|

|||

|

|||

|

Aspire is powerful. But try to think of your 3D area as all pieces of a big puzzle. All multiple layers in a 3D space. When you piece it all together, you have a great work of art. Remember a great piece of art such as a painting started with a single brush stroke. No different when you are working in a 3d environment.

|

|

#515

|

|||

|

|||

|

Thanks, Pete.

The weak link in all this is the 48 yr. old operating system.. namely me. I'm watching the video now. I'm wondering if, after I profile the crown shape with the two rail sweep, if I could apply my carving as a texture, to the crown surface, using the boundary tool? |

|

#516

|

|||

|

|||

|

The operating system isn't weak, it just needs rebooted. The problem with getting old is we forget to think young. The young learn through mistakes and missteps but that does not stop them, they push on. We all need to remember that.

|

|

#517

|

|||

|

|||

|

Darren, I haven't got that far yet either, but as I dig into it deeper I'll let you know something. If its super detailed with under cuts you'll need a 5 axis MM.

Just being able to make a reversed crown on a curve would have saved 100's of man hours on a job years ago, all done by hand, that's when I realized I needed a cnc. Just being able to make a reversed crown on a curve would have saved 100's of man hours on a job years ago, all done by hand, that's when I realized I needed a cnc. |

|

#518

|

|||

|

|||

|

Thanks for the reminder, Pete.

Tom, I've been thinking about undercuts, and I don't think I need to get THAT elaborate.. Thanks again for taking the time to offer your input, its guys like you and all the rest that make this a great place to hang out. |

|

#519

|

|||

|

|||

|

If being young means mistakes and missteps, I can't be more than tree' years old!

|

|

#520

|

|||

|

|||

|

If you do the crown as a two rail sweep, then do the carvings as a separate component, you can have Aspire place an array of components along the crown.

It's hard to see in the pic, but from what I can see on the straight side pieces, there will be undercuts, as you'll be machining it upside down. It really depends on how detailed the carving is and how steep the face of the crown is. |

|

#521

|

|||

|

|||

|

That's exactly what I was wondering, Ger. Thanks for the insight.

I posted the picture as an example, I'd try to model something without undercuts, for simplicities sake. Challenges like this are fun, when there is no deadline looming. |

|

#522

|

|||

|

|||

|

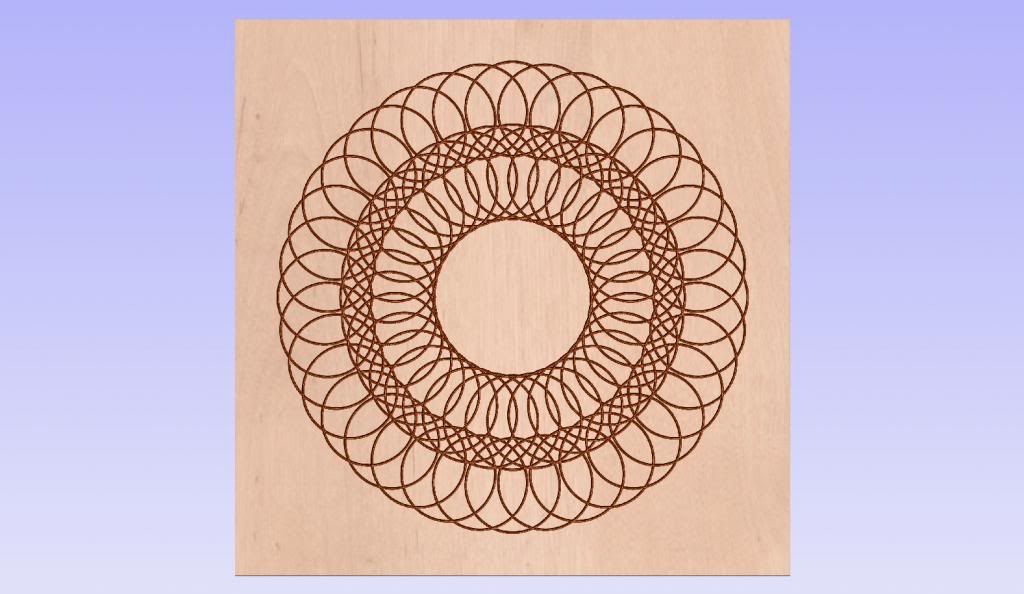

So, I discovered 36 4" circles grouped around an 8" circle with 36 more circles grouped around a 12" circle with the 8 and 12" circles deleted looks just like the Spirograph designs I failed miserably to create as a kid.

|

|

#523

|

|||

|

|||

|

You must have extra time to blow...lol

|

|

#524

|

|||

|

|||

|

It kinda does.

|

|

#525

|

|||

|

|||

|

#526

|

|||

|

|||

|

Ah, nascar driver. Lol

|

|

#527

|

|||

|

|||

|

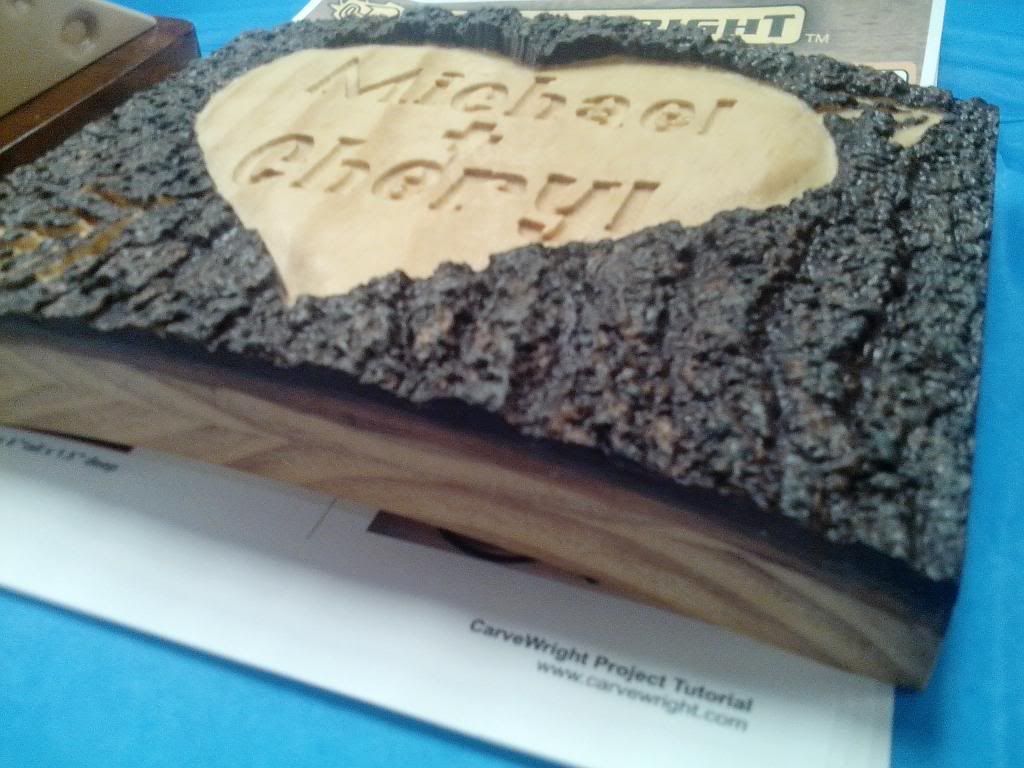

Here is something you might like

|

|

#528

|

|||

|

|||

|

That's cool, Pete. Thanks for sharing.

|

|

#529

|

|||

|

|||

|

Ok, been riding the couch a lot and not getting much done.

I was diagnosed with Lyme Disease about 6 months ago and its been hitting me pretty hard lately. I did get out to the shop over the weekend to do a little show and tell for visiting family... Drew this a while ago and figured I'd cut it out. I'll get it painted and on the shop wall sometime. Wore me out...   |

|

#530

|

|||

|

|||

|

Darren,

Sorry to hear about the Lyme. I had a friend diagnosed with Lyme a bunch of years ago and he had a hard time to get rid of it. Hope they got you on some good antibiotics! |

|

#531

|

|||

|

|||

|

It is really prevalent here as well. Seems like I know at least 2 people a year that get Lyme. Pretty much I gave up hunting because all I got done doing was pulling ticks off my clothes. I seem to find at least one tick every summer on the kids. I hope you get it worked out and get to feeling better. Nice work on the sign!!!

|

|

#532

|

|||

|

|||

|

Thanks for the kind words fellas.

I'm at Jim McGrews in Columbia SC for the next 3 days for an Aspire camp. Hopefully I'll learn a thing or two about designing 3D stuff... |

|

#533

|

|||

|

|||

|

Have fun

|

|

#534

|

|||

|

|||

|

I hope you will post some updates as you go through the course and let us know what all they cover.

|

|

#535

|

|||

|

|||

|

Absolutely!!

|

|

#536

|

|||

|

|||

|

Whew, 3 days hanging out with a bunch of Aspire expert users is kind of mind numbing.

There were several new gadgets previewed that will be available this summer that are very cool to use, such as an automatic dog bone filleter that was demonstrated to find dozens of tabs on 52(!) sheets of a project and insert them with 1 click. IMPRESSIVE!! Best three days I've spent hanging out with 80+ guys who have the same passion for CNC as I do. If you have the chance, try and attend one of these. |

|

#537

|

|||

|

|||

|

So what are you going to teach us first? Don't keep us waiting now, get down to that cnc machine and wow us...

|

|

#538

|

|||

|

|||

|

So, while I appreciate the title change, I like my old one better.

A change back to "Man I'm having fun with this machine" would be appreciated. Here is a sample of the talent at the show and tell portion of the Aspire Camp: I walked by this for two days before I realized it was routed bark, and not a section of a real tree...  |

|

#539

|

|||

|

|||

|

Wow...at first I didn't get what you were saying...very impressive in deed.

Shows me how little I know at this point. Mark |

|

#540

|

|||

|

|||

|

Sooooo, Wed. night I went to dinner with 8 or so other guys from the camp, and the subject got around to "who's machine are you running?"

When I said I have a 5x12 MM, the table got pretty quiet. I jokingly said "as the room goes silent...." A couple guys said they were impressed with the MM design, and one guy said he was in awe of any one who could build their own machine. The owner of a Big Iron (150k+) looked at a couple pics on my laptop and complimented me on a clean build...I went there thinking I might be seen as a second rate machine owner, but I got a lot of respect from everyone, even though its geared toward Camaster owners, and for that I'm grateful. What a great community CNC owners are, for the most part. |

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| University Of Missouri Saint Louis Theater | ganderson | Introduce yourself and start planning | 8 | Fri 31 October 2014 17:53 |

| Starting my MM Build - St Louis MO USA | inventek2000 | Construction started, but not cutting yet | 38 | Sun 25 September 2011 17:51 |

| my machine cnc | marcoscnc29 | Archives | 1 | Sat 24 April 2010 17:58 |