|

|

#121

|

|||

|

|||

|

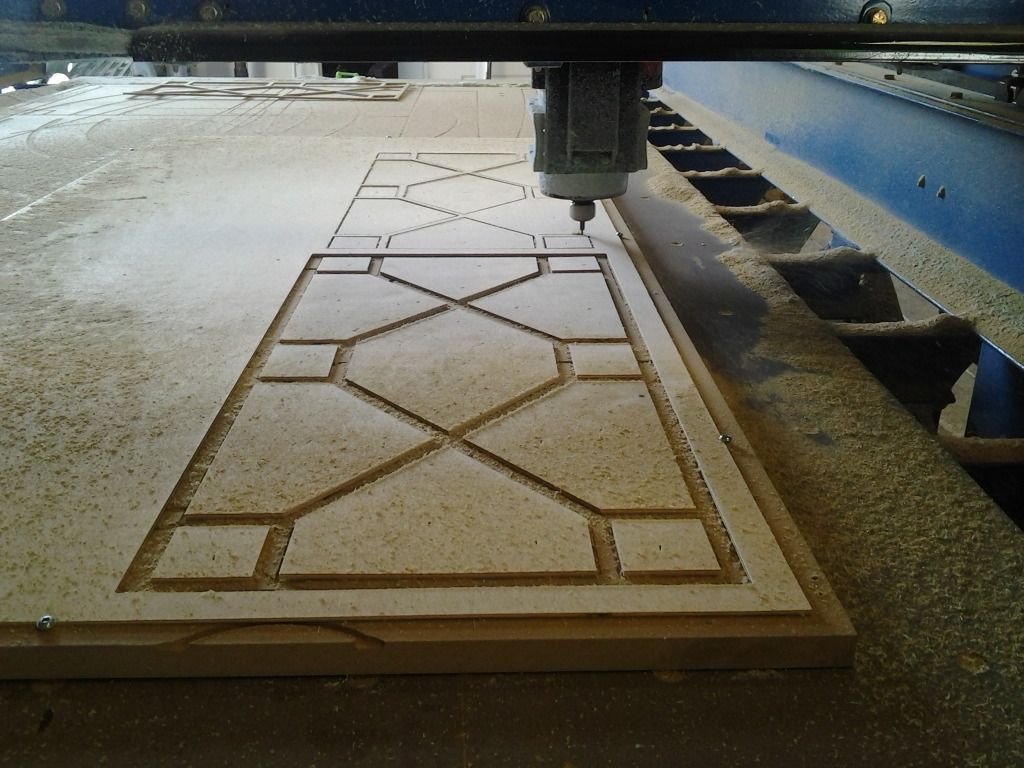

Cutting its very first file.......

Set the steps per inch, loaded a file I used a lot on the little tabletop machine, everything is working exactly as planned. A good day.   Last edited by darren salyer; Wed 27 June 2012 at 07:28.. |

|

#122

|

|||

|

|||

|

Congrats! another number on the way.

|

|

#123

|

|||

|

|||

|

Were on a roll !!! Congrats on your build !!! You get #101

|

|

#124

|

|||

|

|||

|

Good job!

|

|

#125

|

|||

|

|||

|

...pretty belt drives!

Nicely done - is that 3 or 4 machines commissioned this week? |

|

#126

|

|||

|

|||

|

Congrats Darren!

|

|

#127

|

|||

|

|||

|

Builder's Log Update

|

|

#128

|

|||

|

|||

|

4 I do believe.

|

|

#129

|

|||

|

|||

|

Thanks for the kind words everyone.

Also, thanks to everyone who offered words of encouragement or advice through a sticking point. I can't begin to describe the amount of knowledge I feel i've gained from from this project. ( And I'm still clueless compared to most of you.) Thanks Gerald and Mike for the start and continuation of a forum that allows us all to share knowledge and friendship. Soooooooo, now that I have the bug, (And BAD I might add...)I'm seriously contemplating starting a MM based lathe along the lines of Arts (turningaround) . 8-10 feet long material length, 16-20" diameter cutting area. Then I could retire the old Legacy Ornamental Mill... (Already have 2 more 20' main beams..) Anyone want to collaborate on a design, or is that straying too far from the MM premise? Last edited by darren salyer; Sat 30 June 2012 at 15:26.. Reason: spelling |

|

#130

|

|||

|

|||

|

Man, am I having fun with this machine!!

Here is a logo I carved into a piece of Livingstone Solid Surface scrap I had laying around. Size is about 5x9 overall. Logo was carved with an 1/8" endmill .2" deep, and filled with poured epoxy, as a sample. The prospective customer seemed pretty impressed with how it came out. Picture is washed out a little, due to the camera phone pic. Looks much more vibrant in person.  |

|

#131

|

|||

|

|||

|

Looks great Darren!

|

|

#132

|

|||

|

|||

|

Hi Darren

Nice work, may I inquire about how you finished (sanded) the poured epoxy without blemishing the surface finish of the other material. Regards Ross |

|

#133

|

|||

|

|||

|

Since Corian type materials are basically plastic, they can be sanded and buffed just like the epoxy. On this small piece, to speed things, I poured the epoxy while on the spoilboard, and after it cured, I surfaced the whole piece, cutting about .05" off the whole surface, then sanded with my RO sander, working up to 320 grit, then buffed. Took about 15 minutes.

|

|

#134

|

|||

|

|||

|

Thanks Darren

Smart leaving it on the machine to re surface the piece. My motto is always let the machine do the work ! I have been doing some resurfacing of timber drawer fronts myself recently so your method makes perfect sense. Cheers Ross |

|

#135

|

|||

|

|||

|

Darren, I'd be interested in collaborating on a design for a lathe-style MM. I have a Legacy as well, and I can't tell you how much I'd like to be able to replace it with something a little more... robust? And CNC would be a HUGE help for a lot of what I do.

I'm about 2 weeks from finishing my MM (electric cables are en route, last thing I need), and once that is done, I think I will be turning my attention towards a Lathe version. |

|

#136

|

|||

|

|||

|

Sounds great.

The Legacy is OK.... for its era. It always seems that something screws up or comes loose at the very end of a project that ruins it, and all the work setting it up. |

|

#137

|

|||

|

|||

|

Heh, yeah, i have the same issue. And i usually don't notice it....

|

|

#138

|

|||

|

|||

|

small paying job today, but hey, its a start.

Had dust collection hooked up, and it was working great, but it was developing a nasty static charge. I unhooked it until I can get a ground wire into the ducting.  |

|

#139

|

|||

|

|||

|

...ahh the pretty sight of dust everywhere. Well done.

|

|

#140

|

|||

|

|||

|

Dust = Dollars.....

|

|

#141

|

|||

|

|||

|

Did some math....3-4 of these type jobs a day = about 1/2 day of easy work=enough to pay the bills without breaking a sweat=enough time for a hobby.

Why does it never work out like that? |

|

#142

|

|||

|

|||

|

Wait soon the jobs will be lining up and one machine won`t be enough.

|

|

#143

|

|||

|

|||

|

THAT is the dream, Hennie.

|

|

#144

|

|||

|

|||

|

Quote:

You can also wrap some wire loosely outside of the dust collector duct instead of inside of the duct. I use 1mm solid core hook up wire which I happened to have, never have static ever since. In fact any conductor would do. Just remember to tie one end of the wire to ground. any ground would do. |

|

#145

|

|||

|

|||

|

Made myself a cutting board over the weekend.

St. Louis Cardinals logo. |

|

#146

|

|||

|

|||

|

Nice, good fit.

|

|

#147

|

|||

|

|||

|

SAme company I poured the epoxy logos for comissioned me to build an over-the-top "princess chair" for photos of the Birthday Girl at parties held in their store.

Very fun project.  The back started out as a 32" x 48" blank of MDF 3" thick. Hard to see, but the back is concaved about 2 inches. Last edited by darren salyer; Mon 26 November 2012 at 20:10.. |

|

#148

|

|||

|

|||

|

Kids will love that chair. I won't be surprised if the store orders more for sale.

Jason |

|

#149

|

|||

|

|||

|

Thank you, Jason.

Funny you should say that. This is the prototype chair. I was shown 1 picture of a similar chair and told "surprise us" THAT is a pretty scary thing to hear. I've been sweating the details, but the good news is they love it. Now that the design is done and the toolpaths complete, any additional ones are a walk in the park. I wouldn't be surprised if the work for this one company pays for my machine. I'll post some more pics of things we've done for them. |

|

#150

|

|||

|

|||

|

...and that is how you pay for your machine...One really good client.

|

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| University Of Missouri Saint Louis Theater | ganderson | Introduce yourself and start planning | 8 | Fri 31 October 2014 17:53 |

| Starting my MM Build - St Louis MO USA | inventek2000 | Construction started, but not cutting yet | 38 | Sun 25 September 2011 17:51 |

| my machine cnc | marcoscnc29 | Archives | 1 | Sat 24 April 2010 17:58 |