|

|

#91

|

|||

|

|||

|

Russell, cool looking drill.

Tony, you need to cut some steel. That saw is too clean, it needs some dirt. |

|

#92

|

|||

|

|||

|

that cold drill is soo cool...

|

|

#93

|

|||

|

|||

|

Hi,

I have not been able to get the cold saw dirty as yet, as I have been lying flat out in bed since last Saturday with back issues again. So today I ordered our 4 x PMDX-125 Multi-Mode Breakout Boards. I cannot wait to get started on this baby now, but unfortunately I just need to give my back some time to come good again. Cheers Tony. |

|

#94

|

|||

|

|||

|

Sorry to hear your back problem.

I share the same problem, spend a fair bit of money at the chropractitioner far many year. Until I picked up Pilates, I bought a few books & practice at home & after 3 years, the back problem is almost gone. IMHO most back problem is mainly due to bad posture... |

|

#95

|

|||

|

|||

|

Building (and operating) a big MM should carry a warning about potential back problems. This thing is BIG and the parts (+ boards) are heavy. The main table is about at dining table height, which is ideal for a seated operator, but a bit low for stooping.

|

|

#96

|

|||

|

|||

|

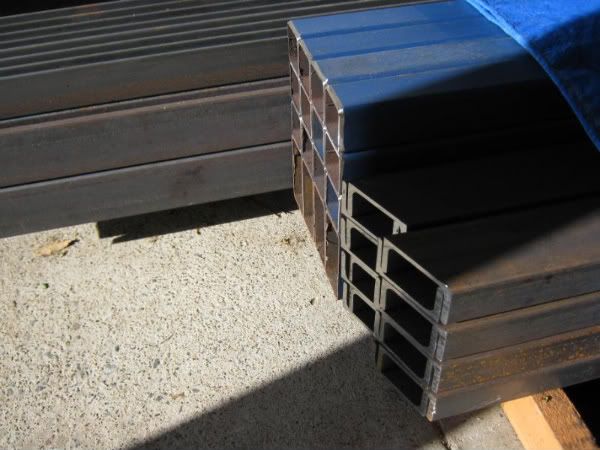

Sparks Flying!!

Hi All,

After a week of resting my back, I decided to make a start on the steel checking and cutting legs, rails and bracing to finished sizes, also ground the ends of the steel in preperation for welding, and cut most of the angles on the bracing for most of the table. The new cold saw works a treat cuts through the steel with ease like cutting butter and is very quick providing a nice clean cut. I also cut all the Y support channels to size and cut the angles to all the ends of these channels also. I still have some more cutting of braces to do but certainly getting there now with not much left to cut. After probably another day of cutting and grinding all the table steel should be finished. Then it will be on to the main X beams and the cutting / grinding of the V angles  So here are some pics from today !! My new Cold Saw finaly got a few scratches on it and got a little dirty   Really pleased and happy with the qaulity of the cuts      All the Y frames pre cut and ready for welding   Cheers Tony. |

|

#97

|

|||

|

|||

|

That's the sort of recovery we like to see Tony. Pleased for you that the cuts have been so accurate.

regards Ross |

|

#98

|

|||

|

|||

|

Just saw the pics it must be great to have the right tools for the job. looks like we may need to start welding soon.

|

|

#99

|

|||

|

|||

|

4 x Bob's have arrived!!

Cheers Tony. |

|

#100

|

|||

|

|||

|

Break out Boards by the handful I see. There has got to be a LOT of wires coming out of those boards. Now call Paul (AKA skippy) and have him go without sleep until a stepper is turning.

Thanks for the steel cuts today - very much appreciated. |

|

#101

|

|||

|

|||

|

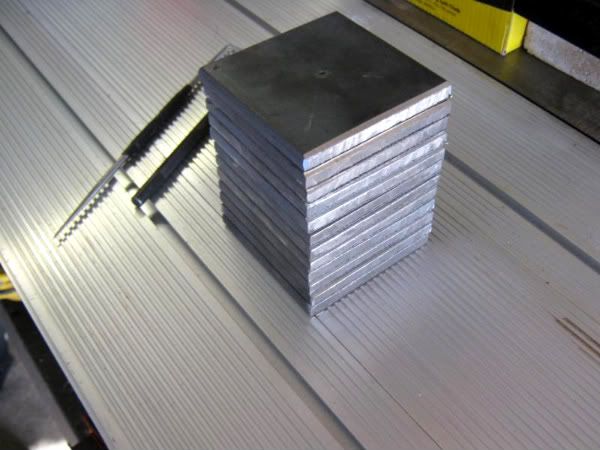

Paul is onto it Ross!! lots of reading being done I think and bits and pieces being sought.

I managed to get a little bit more done later this afternoon, bought the adjustable feet for both tables, they are also on a ball swivel to help take up any out of level discrepencies. I also bought some 75 x 8mm flat bar for the ends of the main X beams and for the foot plates of both tables which I have already cut and ground as well as centre punched ready for drilling and tapping. Cold cut saw is certainly earning its keep  I also managed to cut the bevels on the ends of the Y support channels for the second table this afternoon, so the only thing left to cut now are the table braces for along the length of the X frames for both tables and thats all the steel pre cut, except for the Main X beams and all the V rails, which Im really not looking forward too     Cheers Tony. |

|

#102

|

|||

|

|||

|

HI ALL

I come from Poland and i dont know where to buy laser cut parts and another parts frome some one can help me where i can order for my planing mechmate cnc . thanke you for all |

|

#103

|

|||

|

|||

|

Pm sent Kosta!!

Cheers Tony. |

|

#104

|

|||

|

|||

|

Hi All,

Have not been around much lately, my real job keeps getting in the way  I took some time today and cut the last of the braces for the table. I was also able to cut all the short bevel cuts on one end of the braces but had to cut the other long bevel cut using the thin cutting disc's which worked well. I took some time today and cut the last of the braces for the table. I was also able to cut all the short bevel cuts on one end of the braces but had to cut the other long bevel cut using the thin cutting disc's which worked well.I also cut and bent all the end plates ready for welding to the ends of the main parallel flanged channels which should finish them off nicely!! So now all the steel for both skippy's and my table is pre cut and ready for welding  that is all apart from the cutting and grinding of the v rails and the actual cutting of the angles to the ends of the main parallel flanged channels which I will cut as soon as I can get someone to give me a hand to move them that is all apart from the cutting and grinding of the v rails and the actual cutting of the angles to the ends of the main parallel flanged channels which I will cut as soon as I can get someone to give me a hand to move them Jeeeeezzzzz they are heavy Jeeeeezzzzz they are heavy  should be welding in another week or two hopefully  Cheers Tony. |

|

#105

|

|||

|

|||

|

Got in from work this afternoon and thought I would drill and tap all the foot plates for both our tables.

Was going great until I realised the largest drill bit I had was 13mm and guess what!! I need a 14mm drill bit for a 16mm x 2 tap  So off to the hardware tomorrow to buy a 14mm drill bit. Cheers Tony. |

|

#106

|

|||

|

|||

|

Be careful, a 14mm bit doesn't fit in the common 1/2" chuck. You might need to get a 14mm with "reduced shank" if your chuck can't go bigger.

|

|

#107

|

|||

|

|||

|

Thanks Gerald, as usual you are on the ball

My drill press will take over 14mm so all good but yeh that would catch some out for sure. Thanks Tony. |

|

#108

|

|||

|

|||

|

Drilling and tapping of the foot plates all done!!

we are now ready for the welding of the tables to begin we are now ready for the welding of the tables to begin  Cheers Tony. |

|

#109

|

|||

|

|||

|

Do spend some time dry fitting the foot plates to ensure the tapped holes have enough clearance from the channel walls.

|

|

#110

|

|||

|

|||

|

Hi Ken,

No worries there mate!! the legs of our tables are 75 x 75 x 3mm Box, I have cut 75 x 75 x 8mm flat with an M16 tapped hole in the centre to take the adjustable foot, so well clear of everything. Thanks. |

|

#111

|

|||

|

|||

|

That's great, I had to redo my foot plate because I tried to drill the hole on the centroid of the channel legs

|

|

#112

|

|||

|

|||

|

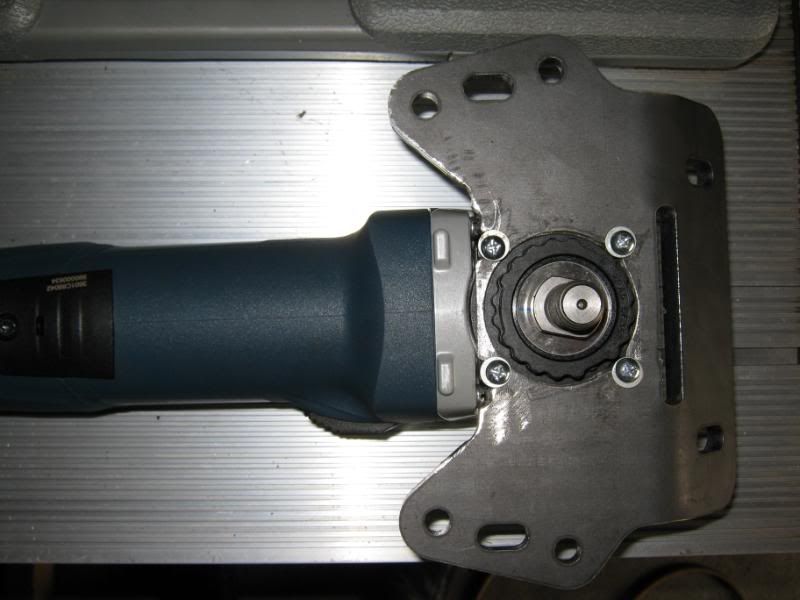

Finally ready to start the rails and Table welding

Finaly managed to get to the local fastner company and picked up some screws to allow attachment of the skate to my Bosch grinder. so all good!!

Skate is sitting nice and flat to the grinder head.  And just for Ken!! here is a photo of our table feet all cut drilled and tapped.  And our gas bottle arrived today also, so we are all ready to rock now!!   Cheers Tony. |

|

#113

|

|||

|

|||

|

Brace yourself for some serious adrenaline rush! WOOHOOO!!!

|

|

#114

|

|||

|

|||

|

I managed to wrestle one of the main X beams up onto my saw stool and made my first cuts on the ends of the main X beams this afternoon using the thin cutting discs. Was surprised at how easy it was to cut them!!

I now need to get cracking with the rest of them, but might need to wait until I can get a hand to move them    Soon be time for the rails  Cheers Tony. |

|

#115

|

|||

|

|||

|

Move the saw to the tool. should save some back strain.

|

|

#116

|

|||

|

|||

|

Hi Again !!

Got busy again today, and managed to get all the main X beams cut for both tables. Now I know why I stuck to working with timber, haha!! much easier to cut and also much lighter to throw around. To be honest I am enjoying the build and the working with the steel  I also spot welded all the bent end plates to all the main X beams and ground them to fit as well as removing all the sharp edges, came up well if I may say so. Especially for an amature  Any way here are the pics from today.    Table is now ready for full build and full welding!!  Cheers Tony. |

|

#117

|

|||

|

|||

|

Nice progress Tony and very neat work.

Regards Ross |

|

#118

|

|||

|

|||

|

Tony,

Good job! By this time, you already know the difference between woodworking & steel working.Your trestle/saw horse looks flimsy for the beams to my eye, do work carefully. Those beams are heavy! Here, we work with the steel as close to ground as possible, especially when working short handed. (have a look at my building log) less lifting & less falling too  Hang in there! |

|

#119

|

|||

|

|||

|

Grest progress Tony. I like steel because you can weld up errors

!!! !!! |

|

#120

|

|||

|

|||

|

Thanks Guys,

I have been doing a little more prep work check measuring everything as well as marking everything and double checking sizes before the welding starts. I am more than happy that everything is now good to go. Not sure on my welding ability though so seeking some help in that department. I might also gain some free welding lessons at the same time  The boss checking the latest progress  The centre legs of the base table in position all straight and square and clamped into position on the main X beams.  Hopefully welding should start very soon, and should not take too long to have both tables complete. Garage is now a little bit better organised with a bit more space to work in, although still needs a little bit more to squeeze both tables in  Cheers Tony. |

|

| Register | Options | Profile | Last 1 | 3 | 7 Days | Search | Today's Posts | Mark Forums Read |

| Thread Tools | |

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Making Skins #74 - Brisbane Australia | Surfcnc | MechMates already cutting | 1078 | Sun 20 September 2015 11:05 |

| Touch Probes Have Arrived #72 - Brisbane, Australia | skippy | MechMates already cutting | 130 | Mon 04 March 2013 04:31 |

| Do my legs look fat? - Brisbane Australia | tangocharlie123 | Construction started, but not cutting yet | 60 | Wed 22 June 2011 06:32 |

| New member - Brisbane Australia | stan stuart | Introduce yourself and start planning | 3 | Tue 11 May 2010 20:48 |

| Commercial Signs | Hugo Carradini | The Show Room | 17 | Wed 21 January 2009 22:51 |