|

|

#121

|

|||

|

|||

|

Sergio,

I don't know Mach3 and I never worked with these sensors. However, it seems like you wired the sensors NO (Normally Open) in series. If any of the sensors switch, then the circuit stays open, they ALL need to switch to close! Instead of using the NO, you might want to use the NC (Normally Closed) connection. I hope it doesn't confuse you if I send this link : http://linuxcnc.org/docs/2.2/html/co...Home-and-Limit (Don't worry about the stepup resistor, you will have it on your BoB) In your case (see first image), you have all switches open and if any of the switches closes, nothing will happen. Change them to NC and it should work fin. About the sound: I that a buzzing sound?? the coils (I think) should be connected to 24VDC, not AC so behind a bridge rectifier. Ries Last edited by riesvantwisk; Sat 15 May 2010 at 07:21.. |

|

#122

|

|||

|

|||

|

Ries

My sensors are wired NO but when they see metal (the rail) then the relays are closed. When 1 sensor is over a hole then the relay opens thus breaking the cicrcuit. There is not a problem with the wiring (i think) since i can see the relays open and close normally. What i don't know is how to set them up in Mach3. Regarding the buzzing of my relays you are suggesting to supply 24VDC instead of 12VDC so to stop the buzzing ?? Sergio |

|

#123

|

|||

|

|||

|

Sergio,

I see what you are saying in regards to the NO/NC situation. With a multimeter you know for sure ... I am not suggesting to move them to 24VDC right now (I did say so in my post and I was wrong there), but check your specifications of the relays when I looked up the specs I did see many different versions, and you could have a 24VDC version aswell as a 12VDC version, specs will tell. In regarding of the buzzing, if it's really buzzing, then this usually means a AC power is used because that would make a relays buzz. A relay shouldn't buzz, just click. If the voltage is to low, then they usually don't buzz, but maby be a tiny bit. I cannot help you with the Mach 3 portion, I use EMC, but I believe for each IN pin Mach3 shows a on-screen indicator. Ries |

|

#124

|

|||

|

|||

|

Sergio, a relay should be silent after switched.

I Have not yet seen a relay that can be operated over the wide range of 12V to 24V DC. Are you quite sure that is the spec.? |

|

#125

|

|||

|

|||

|

Gerald

This is my relay  As you can see the Relay is 12V. The mount can support also a 24V relay. I was wrong about the 12V-24V operation. As you can see in the picture the supply voltage can be either AC or DC but the coil voltage is only DC. So i think Ries might be correct about the buzzing cause my transformer is supplying 12VAC. I'll change my transformer asap and i'll inform again. Gerald can you point me to a thread for setting up my proxies in mach3 cause i can't seem to find anything  . .Sergio |

|

#126

|

|||

|

|||

|

Sergio, that symbol after the 12V means DC. I don't understand why you mention a 12VAC transformer....what are you feeding to the proxies?

For setting up Mach3 with limits and homing, you will have to ask some guys who have already done it (I havn't done it myself). I suspect that it is already set up in Mach3 and that you must only enable all the homes and limits on one pin number. Isn't there a video on that? |

|

#127

|

|||

|

|||

|

Sergio,

you need to get a 12VDC power supply, If you want to make your own then you need a 9VAC power supply + bridge rectifier and condensators. If you happen to have a 9VAC transformer then this is good to experiment with. 9VAC*sqrt(2)-1.4=11.2VDC Here is an example of such power supply : basic-regulated-power-supply.html Some cell-phone chargers do supply 12VDC, or may be you have something laying around to play around with, even if it's 9-10VDC it would work to experiment, don't use that for day to day operation though because a relays need to make a firm contact (well below operating voltage doesn't make a firm contact) or else the contacts will start burning faster. This is also the reason why Mach3 might not see the signal. Last edited by riesvantwisk; Sat 15 May 2010 at 22:37.. |

|

#128

|

|||

|

|||

|

I think that Sergio's relays are chattering on AC and Mach3 can do nothing with that.

Test Mach3's setup with a manual switch, instead of the proxies and relays, and then we will know that side works. |

|

#129

|

|||

|

|||

|

Ries & Gerald

Thx for your help. I switched today to 12VDC and the buzzing is no more. I haven't noticed that my adapter (and not transformer)  was supplying 12VAC.Thx again. So before i continue to plug in my dust collector i better ask again cause as you figured out allready electricity is not my forte. I've bought this dust collector : http://www.rem-maschinen.com/en/Prod...8/Default.aspx and this SSR CKRD2410 : http://www.crydom.com/en/Products/Catalog/c_kr24.pdf I intend to control the SSR from output pin 17. What i need to know is wether the dust collector's operation (switching on/off) from the SSR and not by his switch is causing any kind of problem to the dc motor or not. The dust collector's switch is not a latching one so i think by just press on and then control it's power from the SSR will be ok. Or not ??  |

|

#130

|

|||

|

|||

|

That is quite a small dust collector with only a 550 Watt motor and it should be drawing about 2.5 amps when it is running at full speed. During the start of that motor it will draw over 10 Amps, but the relay (SSR) can handle over-current for a short period. If anything is going to go wrong, it will be with the relay and not with the motor.....motors are tough.

Your theory is correct; leave the DC switched on and the relay, under control of Mach, does the rest. |

|

#131

|

|||

|

|||

|

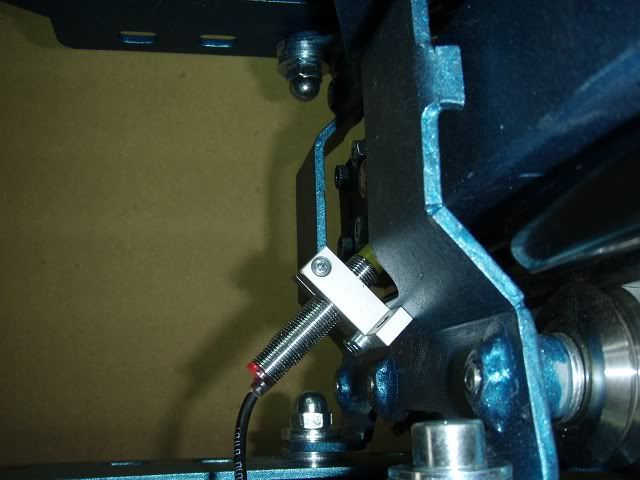

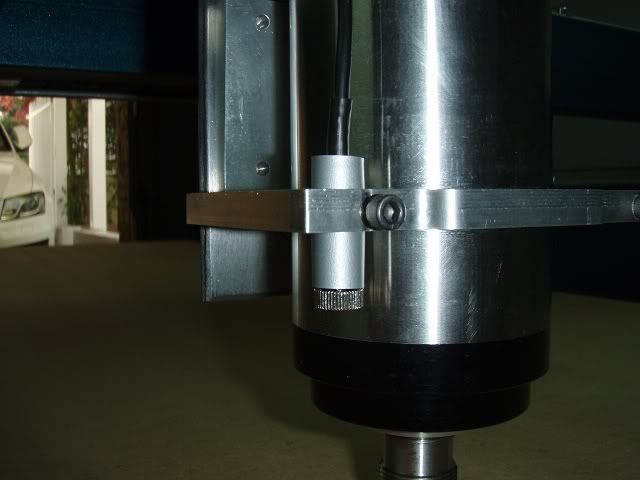

My Precious is making Dust !!!

I'm happy to announce that my MM is finaly got dirty

What else can i say but a big thanks to Gerald, and all the Mechmate community for helping me finish my precious. And here are some pics of it....           I've attached also a cable chain for the Z-Axis   My proximity Sensors   The printer cable exit on the control box  And my control box ready for action  My VFD and a close up of the junction Box with the EMI & Ferrite filters.   My crosshair laser and it's mount on the spindle's mount   My Dust collector (haven't finished the dust shoe and piping yet).  My Z-Zero plate and it's connections on the Y-Car's junction Box   My DIY swinging arm (for carrying the dust collector pipe) using the bearings from the grinding skate.   and some closeups of my wiring   and finally my first cut     and a video of my first cut : http://www.youtube.com/watch?v=OdFd0lKpyRc although i haven't surfaced the table yet the cutting quality was excellent. I guess taking my time and paying a bit more attention to details (levelling etc...) paid up in the end. I think i earned this for today :  and a serial number     Again a big thanks to all. Sergio |

|

#132

|

|||

|

|||

|

Sergio! That is beautiful! Well done!

|

|

#133

|

|||

|

|||

|

Nice work.

Neat and clean. Excellent. Neat and clean. Excellent. |

|

#134

|

|||

|

|||

|

Well done, very very nice looking machine...real professional job.

|

|

#135

|

|||

|

|||

|

That Cohiba and some brandy (or ouzo?) Congrats!

|

|

#136

|

|||

|

|||

|

Congrats! Way to go! Very clean. I like!

Happy cutting! |

|

#137

|

|||

|

|||

|

Nicely done, very neat looking machine - now for the dust...

|

|

#138

|

|||

|

|||

|

Thank you all !!!

I really going to miss the construction part of the MM. Back to computer now    cad,cam,mach,vectors,.tap,g-code......... My head is buzzing allready |

|

#139

|

|||

|

|||

|

Outstanding!

|

|

#140

|

|||

|

|||

|

Sergio - you won't miss the construction part at all.

You will just want to make another machine! Have fun making "stuff". You earned it. Congratulations. Sean |

|

#141

|

|||

|

|||

|

Outstanding!

|

|

#142

|

|||

|

|||

|

Hi Sergio

All so very well thought out, your machine has turned out beautifully. Remember to send in some photos or videos of the things you make using your precious. Regards Ross |

|

#143

|

|||

|

|||

|

Sergio,

Congratulations |

|

#144

|

|||

|

|||

|

Well done and enjoy!

|

|

#145

|

|||

|

|||

|

Like the colour!

|

|

#146

|

|||

|

|||

|

Awesome lookin Machine - You get #61 - Congrats !!!!

|

|

#147

|

|||

|

|||

|

Ok I had this thought about 61 machines and had to share !!! Truely amazing. And how many exist with no serial number !!!

|

|

#148

|

|||

|

|||

|

Thank you all for your comments !!

And thanks a lot Mike for the serial. Hope we reach a 3 digit number  Specs of my MM are : 2050 x 1530, PMDX-125, G203V, Vexta SG-7.2 |

|

#149

|

|||

|

|||

|

Absolutely Love it!! well done Sergio!! very Precious alright!!

Looking forward to more masterpieces from the Precious!!  Awesome Video too, I'm getting excited now!! can you tell!! Cheers Tony. |

|

#150

|

|||

|

|||

|

Well done & detailed Sergio, welcome to the “cutting gang”

Nice details and paint color, well thought out…. Congratulation ! Amicalement, Robert  |

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| I'm BACKKKKKKK!!!! - Houston, TX | swatkins | Construction started, but not cutting yet | 136 | Tue 04 August 2020 23:08 |

| One year later - a report back #29 - Manitoba Canada | astrolavista | MechMates already cutting | 33 | Fri 13 August 2010 14:58 |

| Construction started - Greece | foinikas | Construction started, but not cutting yet | 20 | Thu 31 December 2009 10:13 |

| Hi From Greece (Planning Started, Advise Needed) | Sergio-k | Introduce yourself and start planning | 15 | Tue 17 November 2009 11:35 |

| Terrible thing to see | gmessler | Archives | 2 | Fri 23 November 2007 14:33 |